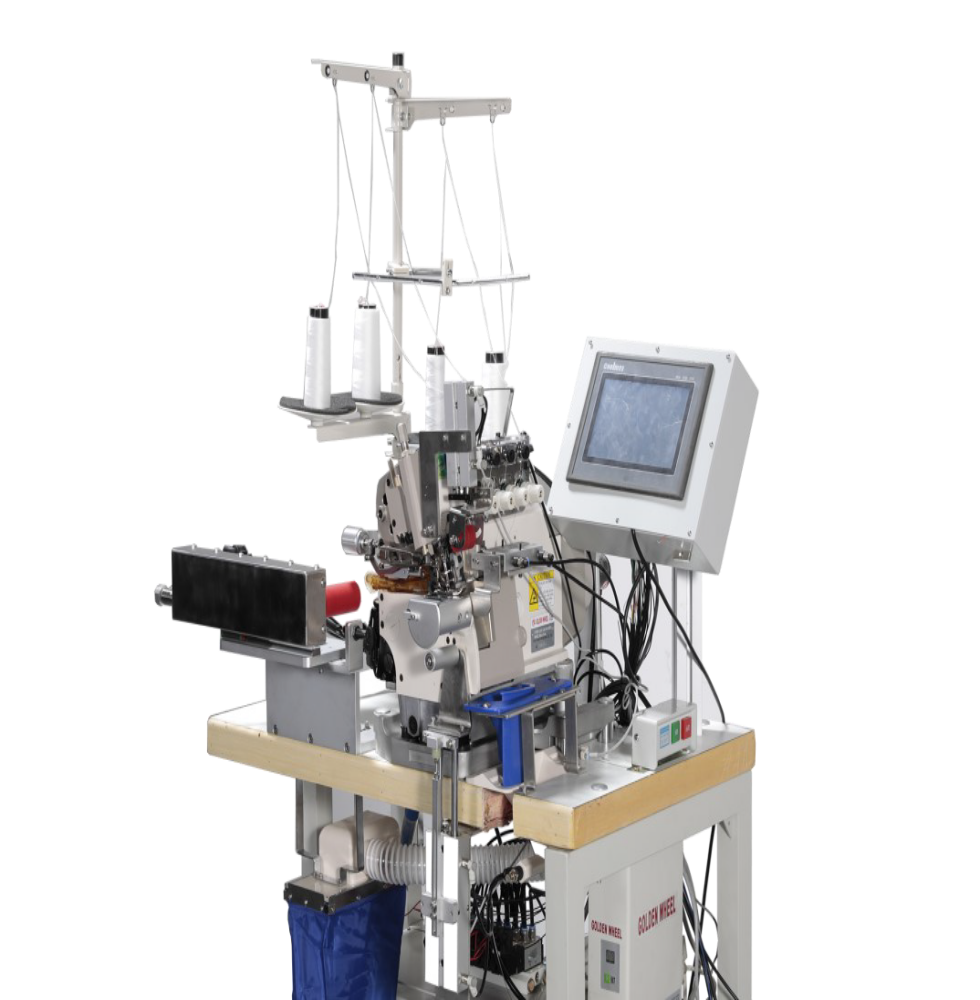

自动上螺纹袖口Self-threading cuff

自动上螺纹袖口

Self-threading cuff

Model:GYD-SLWXK

适用上螺纹袖口,脚口

Suitable for top threaded cuffs, leg openings

功能特点 Features

缝纫脚口袖口罗纹设备

Automatic attach the cuff device.

自动扩张进行尺寸自动控制

Automatic expansion devices for size control.

拖布轮装置,确保完全对齐

Automatic waste collecting device.

车缝完成时自动剪线

The threads are trimmed Automatically when sewing is finished.

料自动收集装置

Automatic waste collecting device.

技术参数 TECHNICAL PARAMETERS

机头型号 sewing head model / 电压 Voltage/ 功率 power PEGASUS:EXT5114-03 / 220V / 550W

气压 Air Pressure / 耗气量 gas consumption 6KG 130L/min

尺寸范围 Size Range 宽度11~20cm,罗纹长不限 Stretchable width range available 11~20cm, Rib length is unlimited

长*宽*高 Length*Width*Height 0*60*141 CM

产能效率(每小时) Production Capacity(per hour)150-190pcs

1.日常服装生产:在衬衫、T 恤、卫衣等日常穿着的服装中,自动上螺纹袖口技术可以高效地完成大量订单的生产任务。确保袖口的美观与舒适,满足消费者对于日常服装品质的要求。

2.时尚服饰制作:对于时尚品牌的服装,精准的自动上螺纹袖口工艺能够提升服装的整体质感和设计感。为设计师提供更多的创意空间,实现独特的袖口设计效果。

1.运动衫和运动裤:在运动服装中,螺纹袖口具有良好的弹性和贴合度,能够适应运动时的身体活动。自动上螺纹袖口制衣技术可以确保袖口在运动过程中不会松动或移位,为运动员提供更好的穿着体验。

2.功能性运动装备:如户外冲锋衣、滑雪服等,需要具备防水、防风等功能。自动上螺纹袖口可以与这些功能性面料完美结合,保证服装的整体性能。

1.企业工作服:对于企业定制的工作服,要求具有统一的外观和质量标准。自动上螺纹袖口制衣技术能够确保每一件工作服的袖口都整齐一致,提升企业形象。

2.制服制作:警察、消防员、医护人员等职业的制服通常需要具备特定的功能和耐用性。自动上螺纹袖口可以为制服提供牢固的袖口连接,满足职业需求。

1.床上用品:在一些高端的床上用品中,如被套、枕套等,也可以采用螺纹袖口的设计。自动上螺纹袖口制衣技术可以为家纺产品增添精致的细节,提高产品的品质感。

2.家居服:舒适的家居服也可以运用螺纹袖口,自动上螺纹袖口技术能够确保家居服的袖口舒适贴合,为人们的家居生活带来更多的便利

First, the clothing manufacturing industry

1. Daily clothing production: In shirts, T-shirts, sweaters and other daily clothing, automatic threaded cuff technology can efficiently complete the production task of a large number of orders. Ensure the beauty and comfort of the cuffs and meet consumers' requirements for the quality of daily clothing.

2. Fashion clothing production: For fashion brand clothing, the accurate automatic threaded cuff process can enhance the overall texture and design sense of the clothing. Provide designers with more creative space to achieve unique cuff design effects.

Second, the field of sportswear

1. Sweatshirts and sweatpants: In sportswear, the threaded cuffs have good elasticity and fit, which can adapt to physical activity during exercise. Automatic threaded cuff garment technology can ensure that the cuffs will not loosen or shift during exercise, providing athletes with a better wearing experience.

2. Functional sports equipment: such as outdoor jackets, ski clothes, etc., need to have waterproof, windproof and other functions. The automatically threaded cuffs can be perfectly combined with these functional fabrics to ensure the overall performance of the clothing.

III. Work clothes and uniform production

1. Enterprise work clothes: For enterprise customized work clothes, it is required to have a unified appearance and Quality Standards. Automatic threaded cuff garment technology can ensure that the cuffs of each work clothes are neat and consistent, and enhance the corporate image.

2. Uniform production: Uniforms for police, firefighters, healthcare workers, and other professions usually require specific functionality and durability. Self-threaded cuffs can provide a strong cuff connection for uniforms to meet professional needs.

Fourth, home textile products

1. Bedding: In some high-end bedding, such as quilt covers, pillowcases, etc., the design of threaded cuffs can also be used. Automatic threaded cuff making technology can add exquisite details to home textile products and improve the quality of products.

2. Homewear: Comfortable homewear can also use threaded cuffs. Automatic threaded cuff technology can ensure that the cuffs of homewear fit comfortably and bring more convenience to people's home life