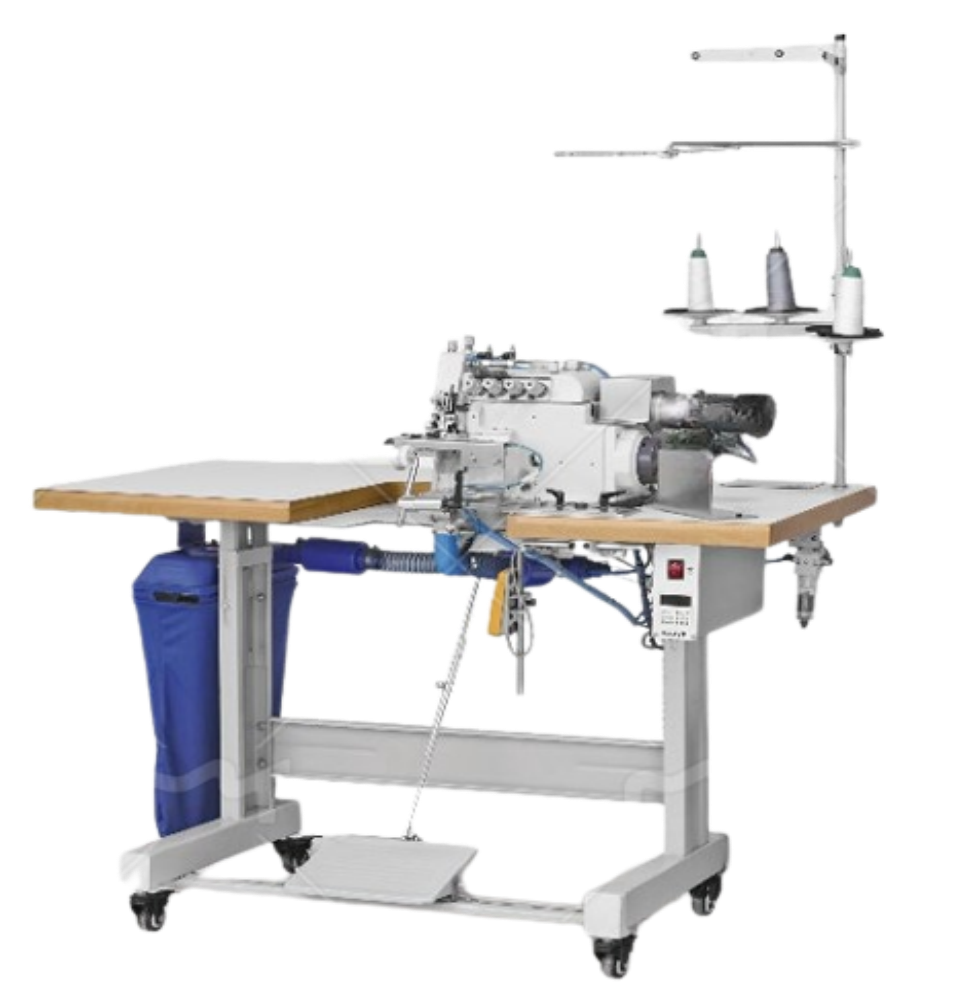

自动上圆领机Automatic round Collar stitching Machine

自动上圆领机

Automatic round Collar stitching Machine

Model:GYD-SLJ

用T-Shirt衫上圆领

Applicable T-Shirt with round neck

功能特点 Features

自动螺纹领定位。

Automatic rib collar positioning.

自动调码。

Automatic size adjustment.

自动上下差动送料,实现可分段性自动容位。

Automatic up and down differential feeding, can achieve segmentable self space- adjustment evenly.

自动螺纹领纠正装置。

Automatic rib-knit collar correction device.

自动倒股

Automatic seam side overlapping.

技术参数 TECHNICAL PARAMETERS

机头型号 sewing head model / 电压 Voltage/ 功率 power PEGASUS:EXT5114-03 / 220V / 600W

气压 Air Pressure / 耗气量 gas consumption 6KG 50L/min

尺寸范围 Size Range可操作直径26~38cm Stretchable diameter range available 26~38cm

长*宽*高 Length*Width*Heigh35*90*161 CM

产能效率(每小时) Production Capacity(per hour190-250pcs