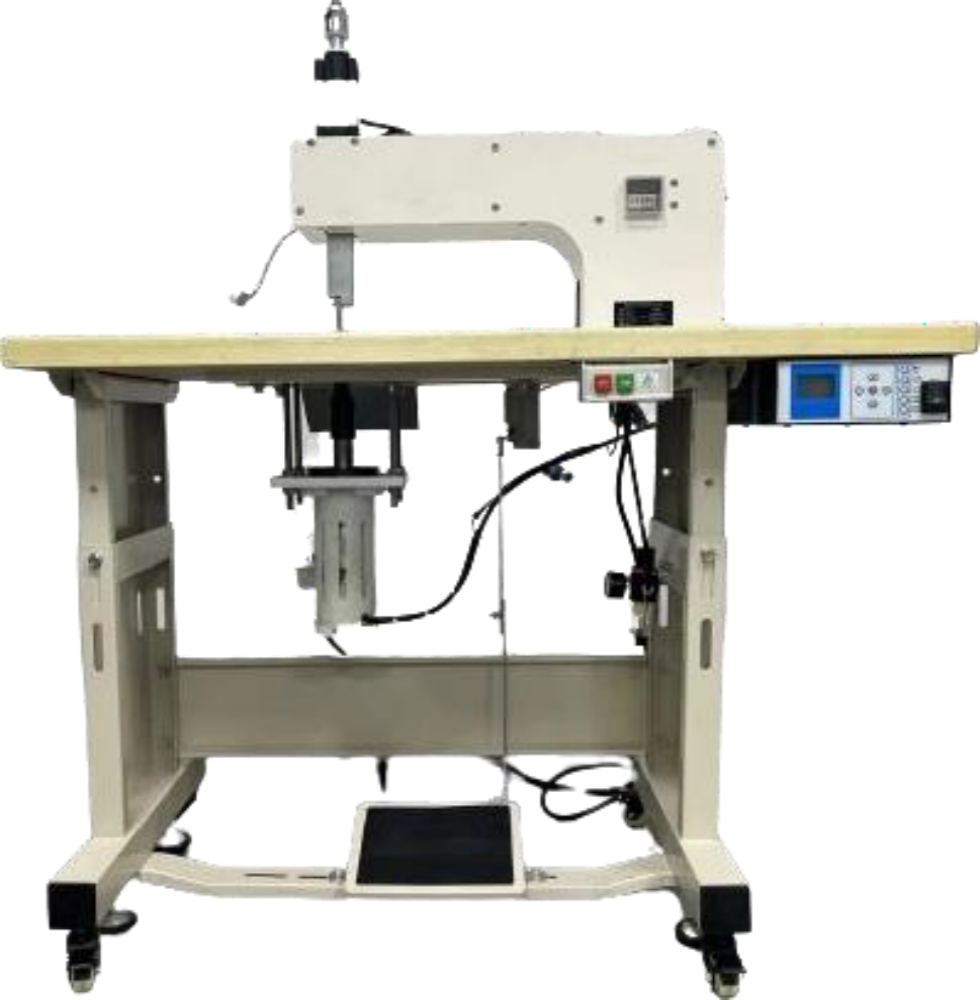

自动超声波切弹力绳机Automatic Ultrasonic Stretch Rope Cutting Machine

自动超声波切弹力绳机

Automatic Ultrasonic Stretch Rope Cutting Machine

功能特点 Features

适合用于制衣,箱包,鞋类,帐篷工厂的 切带

Ideal for cutting tapes in garment, bag, footwear and tent factories.

松紧带弹力绳橡皮筋切带 Elastic band elastic cord rubber band cut tape

用超声波剪切,切口完整美观,切边整齐平滑、无毛边、不散边,剪切效果极佳适应范围广

Using ultrasonic cutting, the incision is complete and beautiful, the cutting edge is neat and smooth, no rough edge, no loose edge, and the cutting effect is excellentWide range of adaptation

可焊拉弹力绳橡皮筋

Solderable elastic cord rubber band

技术参数 Technical Parameters

|

型号model |

JS-QD07/G-UT |

电压Welta |

AC220V |

|

气压Alr pressure |

0.5-0.6 MPa |

裁切方式 Cutting |

自动遍频超声波系统 Auto frequency tracing ultrasonic system |

|

功率Power |

1100W |

系统System |

可编程系统Programmable system |

|

驱动Drive |

伺服闭环系统Programmable system |

缝制Sewing |

|

|

感切角度 Cutting angle |

直裁 cut straight |

作业宽度 Working width |

宽度2-10MM长度30-800MM Width 2-10mm length 30-800mm |

|

体积 Wolume |

长1400MM*宽750MM*1100MMength 1400MM th 750MM He ht 1100MM |

重量Weight |

110KG |

|

产能 Capacity |

长度500MM为例,每分钟产能50-70条 Length 500MM for example, capacity 50-70 strips per minute. |

||