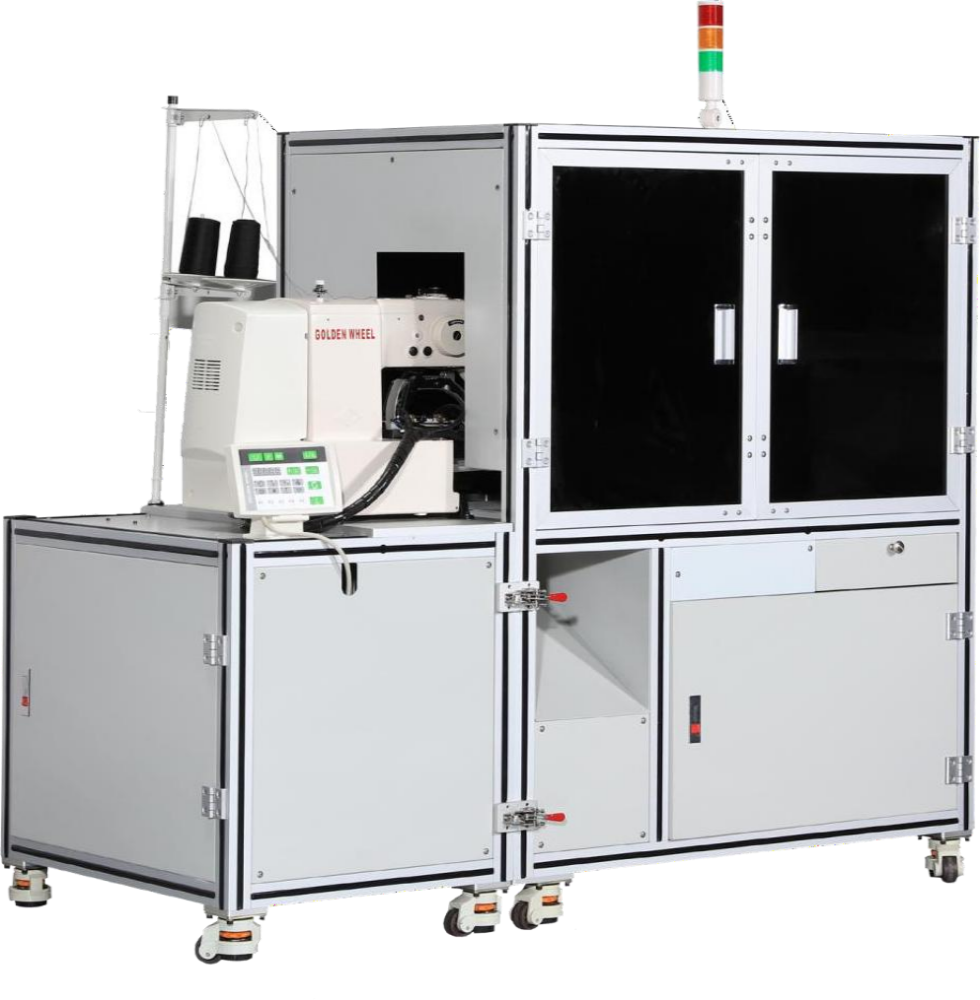

全自动超声波织带折尾套结机Automatic Ultrasonic Ribbon Folding Tail Tackling

全自动超声波织带折尾套结机

Automatic Ultrasonic Ribbon Folding Tail Tackling

功能特点 Features

可适用于衣服配料,背包,手袋,鞋类及适合其他特殊用途

It can be used for clothing ingredients, backpacks, handbags, shoes and other special purpo

主要用于背包织带的折尾车缝

Mainly used for folding tail sewing of backpack webbing

主要应用于箱包背包等各种织带折尾缝制

Mainly used for sewing the tail of various webbing such as bags and backpacks

机器采用全自动追频系统,切口平整柔滑,不烧耗织带,无烟环 保

The machine adopts automatic frequency tracking system, with smooth incision, no burning of ribbon, no smoke and environmental protection

机器多组存储记忆故障断线自动检测自动报警提示

Automatic detection and alarm prompt of broken wires due to multi-group memory failure of the machine

技术参数 Technical Parameters

|

型号model |

JS-TJJ/ZW-UT1 |

电压Welta |

AC220V |

|

气压Alr pressure |

0.5-0.6 MPa |

裁切方式 Cutting |

自动遍频超声波系统 Auto frequency tracing ultrasonic system |

|

功率Power |

1200W |

系统System |

可编程系统Programmable system |

|

驱动Drive |

伺服闭环系统Programmable system |

缝制Sewing |

打枣车Bartack machine |

|

感切角度 Cutting angle |

直裁 cut straight |

作业宽度 Working width |

宽度12-35MM长度100-1000MM对折长度10- 50MM Wdth12-35MML length 10- 1000MM,folding lergth10-50MM |

|

体积 Wolume |

长1600MM*宽750MM*高1450MMLengt 1600MM'Width 750MM'Height 1450MM |

重量Weight |

272KG |

|

产能 Capacity |

长度500MM为例,每分钟产能13-18条 13-18 pleces per minute for 500MM length (as an example) |

||