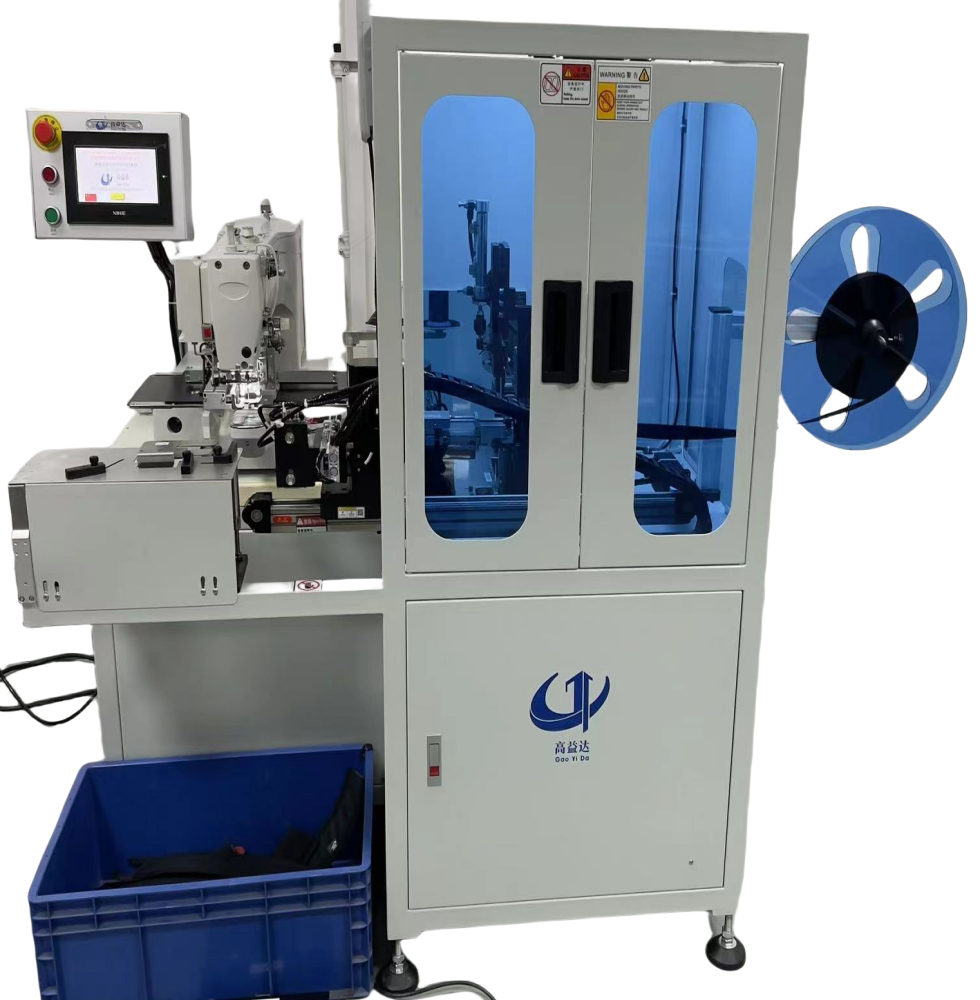

自动超声波肩带穿扣电脑花样机Automatic ultrasonic shoulder strap wearing buckle computerized pattern machine

自动超声波肩带穿扣电脑花样机

Automatic ultrasonic shoulder strap wearing buckle computerized pattern machine

功能特点 Features

可适用于衣服配料,背包,手袋,鞋类及适合其他特殊用途

It can be used for clothing ingredients, backpacks, handbags, shoes and other special purposes

主要用于背包的织带穿扣车缝

It is mainly used for sewing the webbing of backpacks

传统相比较机器缝制出来的产品更加标准美观

Compared to traditional machines, products sewn by machines are more standardized and aesthetically ple

系统设有缺料警报,可预设产品数量,完成产量自动停机

There is a shortage alarm in the system, which can preset the quantity of products and automatically shut down after completing the production

技术参数 Technical Parameters

|

型号model |

JS-CK01-UT |

电压Welta |

AC220V |

|

气压Alr pressure |

0.5-0.6 MPa |

裁切方式 Cutting |

自动遍频超声波系统 Auto frequency tracing ultrasonic system |

|

功率Power |

1200W |

系统System |

可编程系统Programmable system |

|

驱动Drive |

伺服闭环系统Programmable system |

缝制Sewing |

电脑花样机Computers |

|

感切角度 Cutting angle |

直裁 cut straight |

作业宽度Working width |

宽度12-30MM长度100-1000MM对折长度10- 50MM Width 12-30MM Length 100-1000MM Folded length 10-50MM |

|

体积 Wolume |

长1600MM*宽750MM*高1450MMength 1600MM th 750MMHe ht 1450MM |

重量Weight |

280KG |

|

产能 Capacity |

长度500MM为例,每分钟产能12-16条 12-16 pieces per minute for 500MM length (as an example) |

||