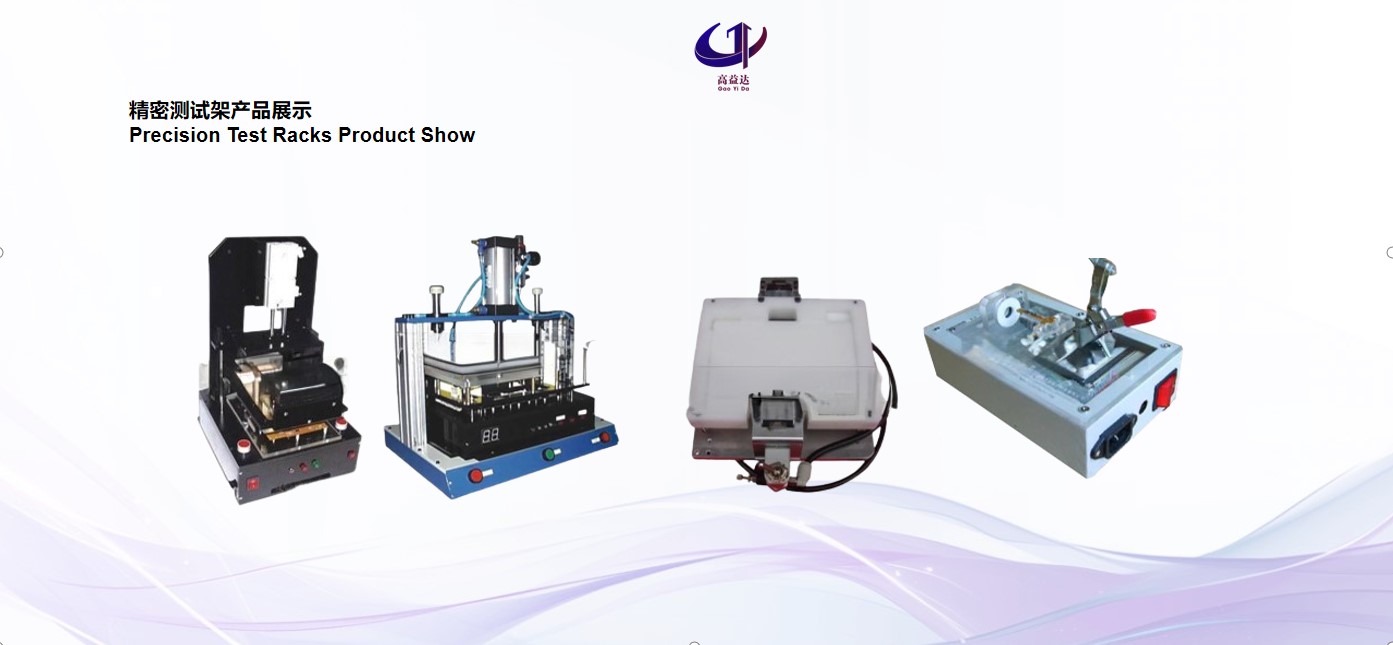

精密测试架产品展示Precision Test Racks Product Show

精密测试架以其高精度测量、多功能测试、稳定可靠、操作简便等特点,成为了各个领域和行业中不可或缺的测试设备。无论是在产品研发、质量控制还是科学研究等方面,都能发挥重要的作用。

Precision test stands, with their characteristics of high-precision measurement, multi-functional testing, stability and reliability, and easy operation, have become indispensable testing equipment in various fields and industries. Whether in product research and development, quality control, or scientific research and other aspects, they can play an important role.

手机生产制造环节:

零部件检测:在手机组装前,对屏幕、电池、摄像头、主板等零部件进行性能测试。例如,使用测试架检测屏幕的显示效果,包括亮度、色彩准确性、分辨率等;测试电池的容量、充电速度和放电性能,以确保电池的质量符合标准;检测摄像头的像素、对焦能力、成像质量等,保证摄像头能够正常工作。

整机功能测试:手机组装完成后,进行全面的功能测试,如开机测试,检查手机能否正常开机、关机,以及开机和关机过程中的电流、电压等参数是否正常;充电测试,验证手机的充电功能是否正常,包括充电速度、充电时的温度变化等;音频测试,检测手机的扬声器、麦克风、耳机插孔等音频部件的功能,确保声音的播放和录制质量;通信功能测试,包括对手机的蓝牙、Wi-Fi、移动网络等通信模块进行测试,确保手机能够正常连接网络、传输数据。

软件兼容性测试:安装不同的操作系统版本、应用程序,测试手机与各种软件的兼容性。例如,测试手机在不同操作系统下的运行稳定性,以及应用程序在手机上的安装、启动、运行、卸载等过程是否正常,以发现潜在的软件冲突或兼容性问题。

手机研发阶段:

新功能验证:当手机厂商研发新的功能或技术时,如新型的指纹识别技术、面部识别技术、无线充电技术等,需要使用测试架对这些新功能进行验证和优化。通过反复测试,收集数据并分析新功能的性能表现、可靠性和稳定性,以便对其进行改进和完善。

性能调试:研发人员利用测试架对手机的硬件和软件性能进行调试。例如,通过测试手机在不同负载下的处理器性能、内存占用情况、图形处理能力等,优化手机的系统设置和算法,提高手机的运行速度和响应能力。

手机维修服务:

故障诊断:当手机出现故障时,维修人员可以将手机连接到测试架上,进行详细的故障诊断。例如,通过测试架检测手机的主板电路是否正常,判断是否存在短路、断路等问题;检测手机的传感器、按键等部件是否工作正常,以确定故障的具体位置和原因。

维修后的检测:在手机维修完成后,使用测试架对手机进行全面的检测,确保手机的各项功能恢复正常。例如,检查维修后的屏幕显示是否正常,摄像头拍照功能是否恢复,充电功能是否正常等,以保证维修质量。

质量检测与认证机构:

质量抽检:质量检测机构和认证机构会使用手机精密测试架对市场上的手机产品进行抽检,以确保手机的质量符合相关标准和规范。例如,对手机的电磁兼容性、辐射安全性、环保性能等进行测试,以保障消费者的使用安全和健康。

认证测试:手机厂商在申请产品认证时,需要将手机送到认证机构进行测试。测试架可以模拟各种使用场景和环境条件,对手机的性能、功能、安全性等进行全面测试,为手机的认证提供数据支持。

教育培训领域:

教学演示:在电子工程、通信工程等相关专业的教学中,教师可以使用手机精密测试架进行教学演示,向学生展示手机的内部结构、工作原理和测试方法,帮助学生更好地理解手机的技术和性能。

实验教学:学生可以在实验室中使用测试架进行手机相关的实验,如手机电路分析、信号测量、功能测试等,通过实际操作提高学生的动手能力和解决问题的能力。

Mobile phone production and manufacturing links:

Parts testing: Before assembling the mobile phone, perform performance tests on the screen, battery, camera, main board and other components. For example, use the test rack to detect the display effect of the screen, including brightness, color accuracy, resolution, etc.; test the capacity, charging speed and discharge performance of the battery to ensure that the quality of the battery meets the standard; test the pixels, focusing ability, imaging quality of the camera, etc., to ensure that the camera can work normally.

Functional testing of the whole machine: After the assembly of the mobile phone is completed, a comprehensive functional test is carried out, such as a power-on test to check whether the mobile phone can be turned on and off normally, and whether the current, voltage and other parameters during the boot and shutdown process are normal; a charging test to verify whether the charging function of the mobile phone is normal, including charging speed, temperature changes during charging, etc.; an audio test to detect the functions of the speaker, microphone, headphone jack and other audio components of the mobile phone to ensure the playback and recording quality of sound; a communication function test, including testing the Bluetooth, Wi-Fi, mobile network and other communication modules of the mobile phone to ensure that the mobile phone can connect to the network and transmit data normally.

Software compatibility testing: Install different operating system versions and applications to test the compatibility of the mobile phone with various software. For example, test the stability of the mobile phone under different operating systems, and whether the process of installing, starting, running, and uninstalling applications on the mobile phone is normal to find potential software conflicts or compatibility issues.

Mobile phone development stage:

New function verification: When mobile phone manufacturers develop new functions or technologies, such as new fingerprint recognition technology, facial recognition technology, wireless charging technology, etc., they need to use test racks to verify and optimize these new functions. Through repeated testing, collect data and analyze the performance, reliability and stability of new functions in order to improve and perfect them.

Performance debugging: R & D personnel use test racks to debug the hardware and software performance of mobile phones. For example, by testing the processor performance, memory usage, graphics processing capabilities, etc. of mobile phones under different loads, optimize the system settings and algorithms of mobile phones, and improve the running speed and responsiveness of mobile phones.

Mobile phone repair service:

Fault diagnosis: When the mobile phone fails, the maintenance staff can connect the mobile phone to the test rack for detailed fault diagnosis. For example, through the test rack to detect whether the main board circuit of the mobile phone is normal, determine whether there are short circuits, open circuits and other problems; detect whether the sensors, buttons and other components of the mobile phone are working properly to determine the specific location and cause of the failure.

Inspection after repair: After the repair of the mobile phone is completed, use the test rack to conduct a comprehensive inspection of the mobile phone to ensure that all functions of the mobile phone return to normal. For example, check whether the screen display after repair is normal, whether the camera camera function is restored, and whether the charging function is normal, etc., to ensure the quality of repair.

Quality inspection and certification bodies:

Quality sampling: Quality testing agencies and certification bodies will use mobile phone precision test racks to sample mobile phone products on the market to ensure that the quality of mobile phones meets relevant standards and specifications. For example, the electromagnetic compatibility, radiation safety, environmental protection performance of mobile phones are tested to ensure the safety and health of consumers.

Certification test: When applying for product certification, mobile phone manufacturers need to send their mobile phones to a certification body for testing. The test stand can simulate various usage scenarios and environmental conditions, conduct comprehensive tests on the performance, function, security, etc. of the mobile phone, and provide data support for the certification of the mobile phone.

Education and training fields:

Teaching demonstration: In the teaching of electronic engineering, communication engineering, and other related majors, teachers can use mobile phone precision test stands to conduct teaching demonstrations to show students the internal structure, working principle, and testing methods of mobile phones, so as to help students better understand the technology and performance of mobile phones.

Experimental teaching: Students can use test racks in the laboratory to conduct mobile phone-related experiments, such as mobile phone circuit analysis, signal measurement, functional testing, etc., to improve students' hands-on ability and problem-solving ability through practical operation.