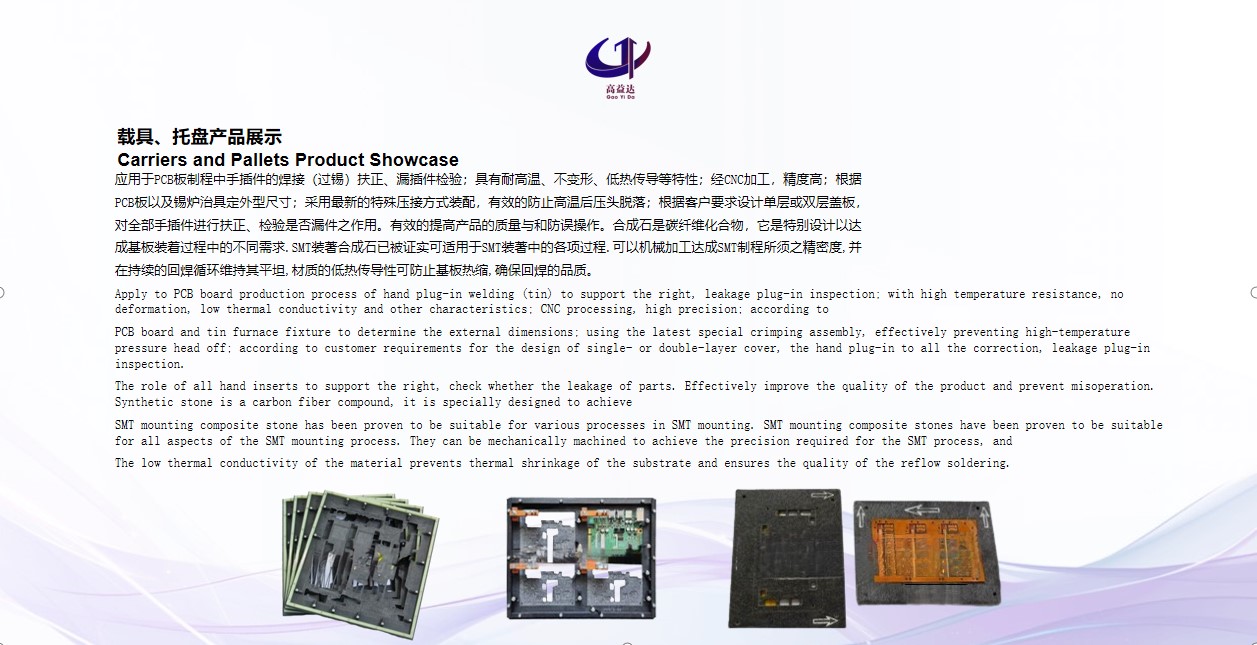

载具、托盘产品展示Carriers and Pallets Product Showcase

应用于PCB板制程中手插件的焊接(过锡)扶正、漏插件检验;具有耐高温、不变形、低热传导等特性;经CNC加工,精度高;根据 PCB板以及锡炉治具定外型尺寸;采用最新的特殊压接方式装配,有效的防止高温后压头脱落;根据客户要求设计单层或双层盖板, 对全部手插件进行扶正、检验是否漏件之作用。有效的提高产品的质量与和防误操作。合成石是碳纤维化合物,它是特别设计以达 成基板装着过程中的不同需求.SMT装著合成石已被证实可适用于SMT装著中的各项过程.可以机械加工达成SMT制程所须之精密度,并 在持续的回焊循环维持其平坦,材质的低热传导性可防止基板热缩,确保回焊的品质。 Apply to PCB board production process of hand plug-in welding (tin) to support the right, leakage plug-in inspection; with high temperature resistance, no deformation, low thermal conductivity and other characteristics; CNC processing, high precision; according to PCB board and tin furnace fixture to determine the external dimensions; using the latest special crimping assembly, effectively preventing high-temperature pressure head off; according to customer requirements for the design of single- or double-layer cover, the hand plug-in to all the correction, leakage plug-in inspection. The role of all hand inserts to support the right, check whether the leakage of parts. Effectively improve the quality of the product and prevent misoperation. Synthetic stone is a carbon fiber compound, it is specially designed to achieve SMT mounting composite stone has been proven to be suitable for various processes in SMT mounting. SMT mounting composite stones have been proven to be suitable for all aspects of the SMT mounting process. They can be mechanically machined to achieve the precision required for the SMT process, and The low thermal conductivity of the material prevents thermal shrinkage of the substrate and ensures the quality of the reflow soldering.

1.标准化作业:载具托盘治具具有统一的规格和设计,能够实现标准化的生产和物流作业。这使得不同环节的操作更加规范和高效,减少了因尺寸不统一或操作不规范而导致的时间浪费。例如,在自动化生产线上,载具托盘治具能够与设备完美配合,实现快速的上料、下料和加工过程,大大提高了生产效率。

2.快速搬运和装卸:其设计便于搬运和装卸,可以使用叉车、输送机等设备进行快速操作。相比传统的人工搬运方式,大大节省了时间和人力成本。例如,在物流仓库中,载具托盘治具可以快速地在货架和运输车辆之间进行转移,提高了货物的出入库速度。

3.减少等待时间:由于载具托盘治具能够稳定地承载物品,减少了物品在运输和加工过程中的晃动和损坏风险。这使得生产过程更加流畅,减少了因物品损坏而导致的等待和维修时间。例如,在电子产品制造中,载具托盘治具可以保护精密电子元件,避免因碰撞而损坏,从而保证了生产的连续性。

1.稳定承载:载具托盘治具通常具有坚固的结构和良好的承载能力,能够稳定地承载各种物品。这可以防止物品在运输和存储过程中因晃动、倾斜或掉落而损坏。例如,在重型机械制造中,载具托盘治具可以安全地承载大型零部件,确保其在运输过程中不受损坏。

2。防护设计:一些载具托盘治具还具有防护设计,如围挡、缓冲材料等,可以进一步保护物品免受外力冲击和碰撞。例如,在玻璃制品运输中,载具托盘治具可以配备柔软的缓冲材料,防止玻璃在运输过程中破碎。

3.防静电和防潮:对于一些对静电和湿度敏感的物品,如电子元件、药品等,载具托盘治具可以采用防静电和防潮材料制作,或者进行特殊的处理,以保护物品的质量和性能。例如,在电子制造行业,防静电载具托盘治具可以有效地防止电子元件因静电而损坏。

1.电路板生产:在电路板的制造过程中,载具托盘治具用于承载和运输电路板。它可以确保电路板在各个生产环节中保持稳定,防止碰撞和损坏。例如,在印刷电路板(PCB)的贴片、焊接和检测等工序中,载具托盘治具可以与自动化设备配合,实现高效的生产流程。

2.电子元件存储和运输:对于小型电子元件,如芯片、电阻、电容等,载具托盘治具可以提供有序的存储和方便的运输方式。这些治具通常具有防静电功能,以保护敏感的电子元件免受静电损害。例如,在电子元件的仓库存储和生产线配送过程中,载具托盘治具可以提高物流效率,减少元件的丢失和损坏。

1.汽车零部件生产:在汽车零部件的生产线上,载具托盘治具用于承载和运输各种零部件,如发动机缸体、变速器壳体、轮胎等。它可以适应不同尺寸和形状的零部件,提高生产效率和质量。例如,在汽车组装过程中,载具托盘治具可以将零部件准确地输送到装配工位,减少人工搬运和操作的误差。

2.汽车总装线:在汽车总装线上,载具托盘治具用于承载汽车车身,使其在各个装配工位之间移动。这些治具通常具有高度的稳定性和精度,可以确保车身在装配过程中的位置准确无误。例如,在汽车喷涂、内饰安装和电气系统装配等环节中,载具托盘治具可以提高生产效率和质量,降低生产成本。

1.货物存储和运输:载具托盘治具是物流行业中常用的货物存储和运输工具。它可以与叉车、输送机等设备配合使用,实现货物的快速装卸和搬运。例如,在仓库中,载具托盘治具可以将货物整齐地堆放在货架上,提高仓库的空间利用率;在运输过程中,载具托盘治具可以保护货物免受挤压和损坏,确保货物的安全到达目的地。

2.物流配送中心:在物流配送中心,载具托盘治具用于货物的分拣、配送和存储。它可以根据不同的货物类型和配送需求进行定制,提高物流配送的效率和准确性。例如,在电子商务物流中,载具托盘治具可以快速地将货物分拣到不同的配送区域,提高订单处理速度和客户满意度。

1.药品生产:在药品生产过程中,载具托盘治具用于承载和运输药品原料、中间体和成品。它可以确保药品在生产过程中的卫生和安全,防止交叉污染。例如,在药品的灌装、包装和检测等工序中,载具托盘治具可以与自动化设备配合,实现高效的生产流程。

2.医疗器械生产:对于医疗器械的生产,载具托盘治具同样具有重要的应用价值。它可以承载和运输各种医疗器械零部件,如注射器、输液器、手术刀等。这些治具通常具有防静电、耐腐蚀等特性,以满足医疗器械生产的特殊要求。例如,在医疗器械的组装和包装过程中,载具托盘治具可以提高生产效率和质量,确保医疗器械的安全性和可靠性。

1.食品行业:在食品生产和加工过程中,载具托盘治具用于承载和运输食品原料、半成品和成品。它可以确保食品在生产过程中的卫生和安全,防止污染。例如,在食品的包装、存储和运输过程中,载具托盘治具可以与自动化设备配合,实现高效的生产流程。

2.化工行业:对于化工产品的生产和运输,载具托盘治具可以提供安全、可靠的承载和运输方式。它可以防止化工产品泄漏和挥发,保护操作人员的安全。例如,在化工原料的存储和运输过程中,载具托盘治具可以与密封容器配合使用,确保化工产品的安全运输。

3.印刷行业:在印刷行业中,载具托盘治具用于承载和运输印刷纸张、油墨等材料。它可以确保材料在印刷过程中的平整和稳定,提高印刷质量。例如,在印刷机的上纸和收纸过程中,载具托盘治具可以与自动化设备配合,实现高效的印刷生产流程